When it comes to septic systems, the drainfield is just as crucial as any other component. At ACE Septic & Waste, we understand the importance of a well-functioning drain field and want you to know more about your own system, including how to maintain it properly. As part of our continuing education efforts, this article will cover the materials and construction of the drain field.

A drainfield, also known as a leach field or absorption field, is where the final treatment of wastewater occurs in a septic system. After solids settle in the septic tank, the remaining wastewater flows to the drainfield, which percolates into the soil. This natural process removes harmful bacteria and nutrients, making the wastewater safe to re-enter the groundwater system.

Drainfield Materials

The materials used in constructing a drainfield are specifically chosen for their effectiveness. The standard conventional drainfield will use the following:

Pipes

Most conventional drain fields will use a series of pipes to distribute effluent from the septic tank throughout the drainfield area.

- Material: These pipes are typically made from PVC (polyvinyl chloride). PVC is favored because it’s durable, corrosion-resistant, and relatively easy to install. You might find some older systems using clay or concrete pipes, but they aren’t used in new installations today.

- Design: The pipes are perforated with small holes or slots along the length of the drainfield. These openings allow the effluent to seep out evenly into the soil. The design and size of the holes are carefully measured to ensure even distribution.

- Installation: Pipes are laid in trenches that are typically about 18 to 36 inches wide and deep (depending on building codes and local or environmental regulations). The pipes and trenches are slightly sloped to facilitate the gravity-fed flow of the effluent.

- Maintenance: These pipes must remain free of roots and other obstructions to prevent clogging and ensure long-term functionality. Regular inspections and occasional flushing can help maintain their performance.

- Regulations: The installation of these pipes, including their material, diameter, perforation pattern, and layout in the drain field, must comply with local building codes and environmental regulations, which can vary significantly by location.

Gravel/Coarse Sand

The gravel (or septic sand) layer surrounding the pipes supports wastewater filtration and prevents the surrounding soil from clogging the perforations in the pipes. This layer also helps distribute the flow of wastewater evenly across the field.

- Support and Protection: It supports the pipes, keeping them in place, and protects them from being crushed by the soil above.

- Filtration: Gravel and coarse sand help to prevent fine soil particles from entering the pipes, which can lead to blockages.

- Fluid Distribution: These materials aid in the even distribution of effluent as it exits the pipes, dispersing the flow to increase the contact area with the soil for better filtration.

- Prevention of Soil Clogging: Providing a transition layer between the perforated pipes and the surrounding finer soil, gravel, and sand prevents the smaller soil particles from clogging the drainage holes in the pipes.

Soil

The soil underneath and surrounding the drainfield acts as a natural filter, removing harmful pathogens and nutrients from the effluent before it reaches groundwater. Here’s what makes soil so important:

- Texture and Composition: Different soil types have varying filtration capabilities, affecting the overall efficiency of the drainfield. This soil texture (the size distribution of soil particles) significantly affects its percolation rate. Sandier soils, for example, are preferred for their higher permeability than clay soils.

- Percolation Rate: This rate determines how fast the effluent filters through the soil. A percolation test will be conducted during the design stage of a drainfield installation project, ensuring the soil can adequately filter and clean the wastewater.

- Biological Activity: The soil contains microorganisms that help degrade and treat the effluent. These aerobic and anaerobic bacteria are vital for breaking down organic matter.

Both the soil and the gravel/coarse sand layers are integral to the effectiveness and longevity of a drainfield. They work together to ensure the wastewater is adequately treated through physical filtration and biological processes before it returns to the environment.

Construction of a Drain field

The construction of a septic drain field will consider the local soil conditions, the size of the septic tank, and the overall wastewater output of the household. Here are the general steps involved in constructing a drainfield:

- Site Evaluation and Preparation: Before installation, a soil test—often referred to as a percolation test—is performed to determine the soil’s absorption rate. This test helps in deciding the appropriate size and type of drainfield.

- Trenching: Trenches are typically 1 to 3 feet wide and up to 36 inches deep, depending on local regulations and soil conditions. These trenches will house the perforated pipes and gravel.

- Laying Pipes and Gravel: Perforated pipes are laid in the trenches on gravel or septic sand. More gravel is then poured over and around the pipes to ensure adequate coverage.

- Covering the Trenches: Once the pipes and gravel are in place, a layer of geotextile fabric might be used to cover the gravel. This fabric prevents the migration of soil particles into the gravel while allowing water to pass through. The trenches are then filled with more soil, bringing the surface level with the rest of the yard.

Choose ACE Septic & Waste for your septic needs

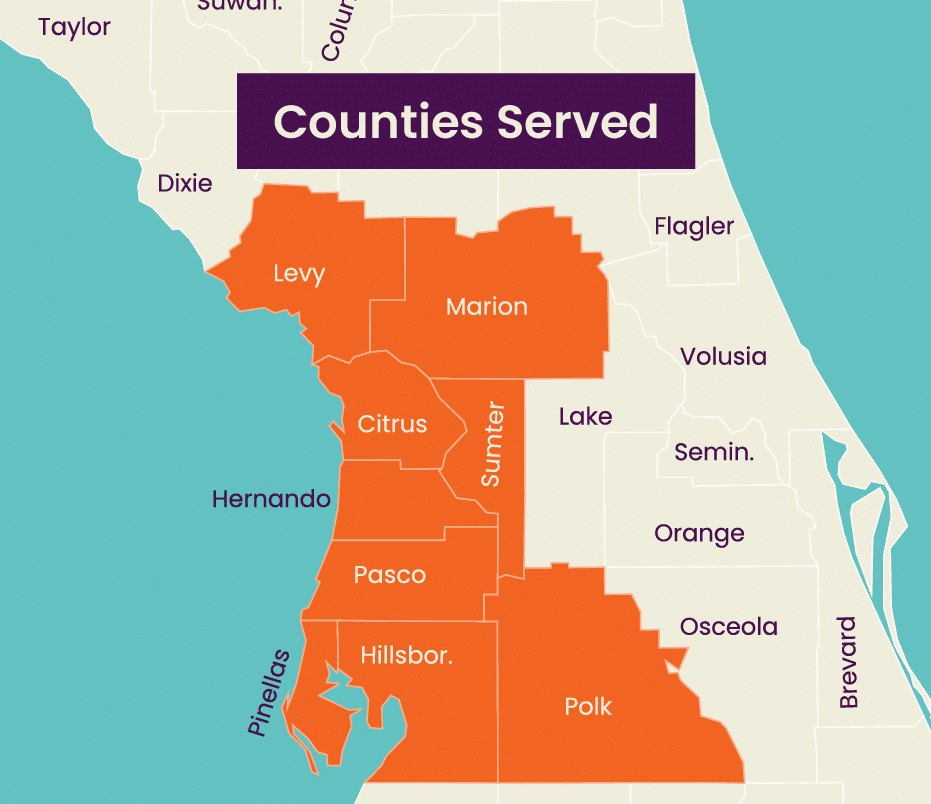

At ACE Septic & Waste, we bring years of experience and expertise to every project. Our team is well-versed in the local regulations and environmental considerations of the Tampa Bay and Central Florida area, ensuring that your septic system, including your drainfield, is built to last and performs efficiently. We offer comprehensive septic system services, from installation to maintenance and repair. Contact us today for more information on our services or to schedule an appointment.