Condition-Based Maintenance

When it comes to your septic system, you want to implement a system that allows you to be cost-effective and proactive in preventing emergencies. A condition-based septic system maintenance approach could end up saving Florida homeowners from the hassle of costly repairs.

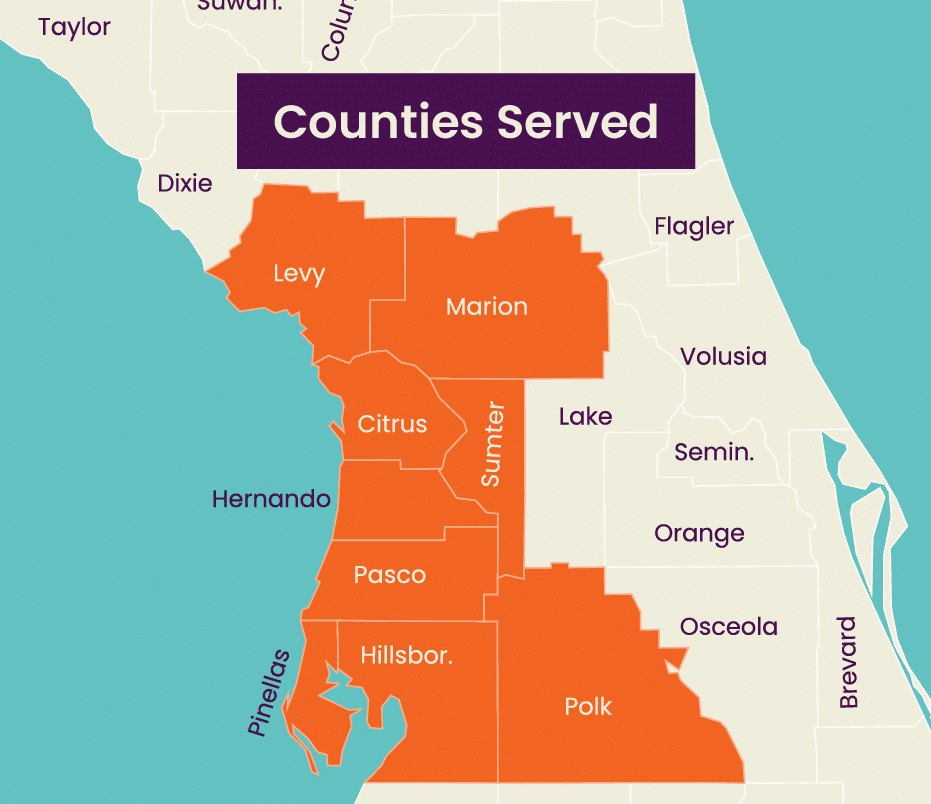

According to the State of Florida, condition-based maintenance primarily requires getting inspections and pumping every three years. If you’re wondering “where I can find a septic tank inspection near me,” a trusted Tampa septic company like ACE can help. A proactive septic inspection is usually a fraction of the cost of an emergency that can run your septic bill into the thousands.

A properly functioning septic system is critical to preserving your home’s value and is usually a key consideration in the home buying process. It’s never too early to schedule an inspection!

Fix only what you need

A main benefit of condition-based maintenance is that an inspection of your private septic system highlights the parts of your septic system that need to be fixed. Rather than waiting for an emergency to come up, in which the entire septic system might need replacing, an inspection can guarantee what needs to be fixed now vs. later. This can help keep costs affordable, repairs on schedule, and give you peace of mind in knowing that your septic system is in good shape.

Many families in the greater Tampa area trust ACE because of our ability to quickly inspect, assess, and recommend necessary services to our customers. Our ACE Exprestimate comes in handy if you do end up in an emergency situation and need answers fast.

Condition-based maintenance is here to stay. It’s even being adopted at municipal levels. Keep reading to find out more.

Condition-based maintenance at the municipal level

Government agencies have dedicated a lot of time, resources, and taxpayer money to overseeing their municipalities’ onsite wastewater treatment systems (OWTS). The conventional method of managing and maintaining these systems has largely been through “time-based maintenance.” Governments large and small should consider switching their septic system maintenance strategy from time-based to condition-based.

Unlike the septic tanks of private residences, municipal sewage systems are far more complex and robust. Some municipalities have hundreds of miles of pipes that at some point or another are going to require maintenance.

What Is Time-Based Maintenance?

Time-based maintenance for central septic systems requires routine maintenance of every pipe in the system on a fixed schedule. In fact, some utilities require the entire system to be cleaned yearly. Others demand only a certain percentage of the pipes be cleaned on a yearly basis, but still on a fixed schedule.

This strategy is undoubtedly an example of working hard, but not necessarily working smart. When pipes get cleaned on a fixed timeline, it can create unnecessary problems and complications, despite best efforts. These complications include:

- Cleaning pipes that don’t need to be cleaned.

- Neglecting a pipe that desperately needs attention due to blockage, and may not receive the appropriate attention for a few years.

- Requiring more taxpayer dollars than necessary to clean pipes on a fixed schedule. This inevitably requires a more costly and robust labor force.

Much of the time-based maintenance strategy rests on hope. You are hoping that you’re cleaning the right pipe, at the right time—and dedicating a lot of resources in the process.

What Is Condition-Based Maintenance?

As the name suggests, condition-based maintenance is the process of cleaning pipes based on their condition or status. This means that pipes get cleaned when they need to be, and not on a fixed timeline. This can save taxpayer money by optimizing the labor force, and can go a long way in cultivating a superior central septic system maintenance plan.

While it all sounds great in theory, there is often one pressing question when it comes to condition-based maintenance:

How do you determine when a pipe is in a condition to require maintenance?

Central septic systems by nature are underground, delicate, and difficult to access. Being able to properly and efficiently assess the condition of a pipe is where technology has to be a creative solution to a long-standing problem.

The InfoSense, Inc. Presentation at WWETT 2022

The ACE Septic & Waste team was fortunate enough to attend the 2022 WWETT Conference in Indianapolis, where we met Alex Churchill, CEO and Corporate Secretary/Treasurer of InfoSense.

InfoSense is the inventor of the SL-RAT. The SL-RAT is a machine that can inspect pipes using acoustic-based technology. Utilizing two adjacent manholes, the SL-RAT leverages a transmitter and a receiver to provide an understandable, straightforward score about the blockage in any given section of pipe.

Through projecting an over 100 dB sound from the transmitter into the manhole, a very loud “yell” gets injected into the airflow of the pipe. The SL-RAT’s receiver, ideally sitting one manhole away, provides a signal score that determines the blockage levels of that section.

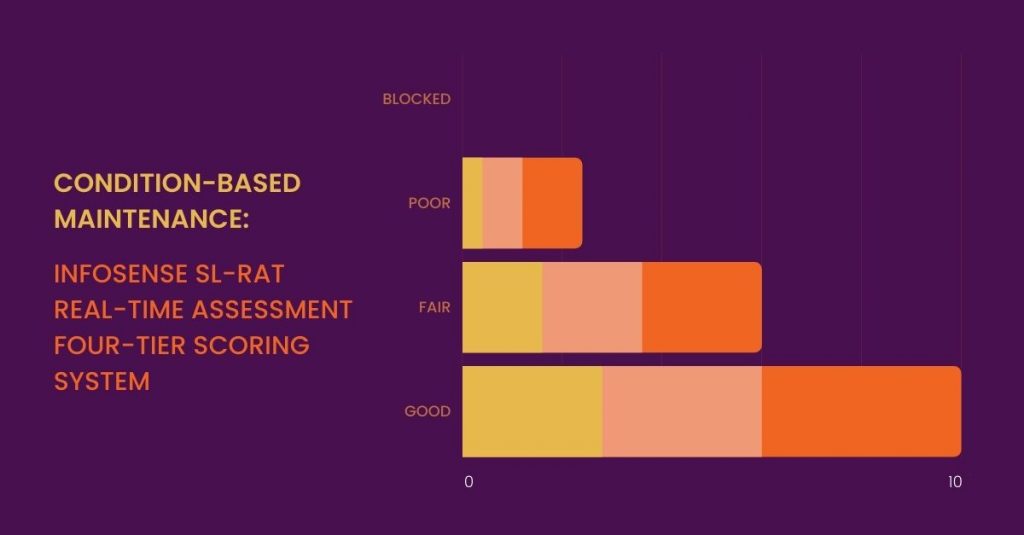

This real-time assessment of any given section of the system is done through a four-tier scoring system.

- Blocked (Score of 0)

- There is something physically blocking the transmitter. This can be either a blockage or a sagging pipe creating an unhealthy water level (aka full belly). A score of zero should trigger immediate inspection with CCTV.

- Poor (Score of 1-3)

- The receiver registers a score, but the signal back is weakened due to a significant degree of blockage in the pipe. Further inspection utilizing CCTV is highly recommended.

- Fair (Score of 4 – 6)

- A minor blockage was detected. Depending on the resources of the municipality, further inspection may or may not be necessary.

- Good (Score of 7-10)

- The pipe is in good condition and further inspection is not necessary.

ACE Septic & Waste was able to sit in on Mr. Churchill’s presentation about InfoSense’s technology, which included a display of his product and compelling case studies demonstrating its effectiveness.

At WWETT, the ACE team learned that the SL-RAT comes with compelling features including:

- The ability to inspect 10,000 – 20,000 feet of pipe per day.

- Assessment scores delivered in under 3 minutes.

- Cost savings estimated between 1/10 and 1/20 of CCTV or cleaning.

- No flow contact.

- No confined space entry.

- Users of the SL-RAT can either go upstream or downstream.

The results speak for themselves. Within the first 400 million feet of pipe inspected by the SL-RAT, roughly 70% of the pipes in most systems were registered as not requiring maintenance.

SL-RAT Case Studies

The SL-RAT has been adopted by municipalities all over the world, and with an impressive array of case studies to show for it.

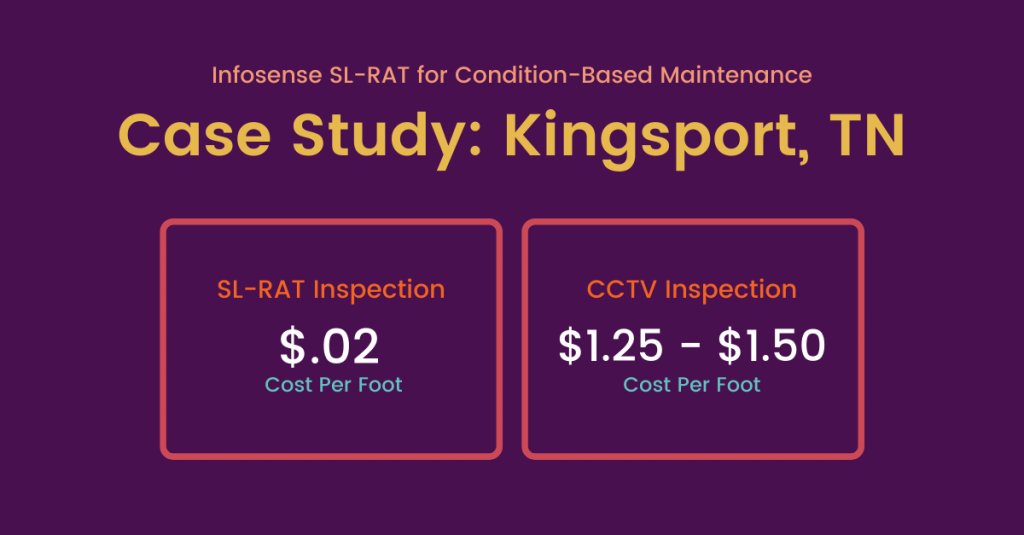

Specifically, the Kingsport, TN case study continues to be a flagship example of the SL-RAT’s capabilities, with Kristen Steach, Wastewater Technical Services Coordinator for the city stating that it costs, “around two cents for every foot to perform that inspection, as opposed to $1.25 – $1.50 per foot for CCTV.”

See more case studies of the SL-RAT here.

A More Efficient Wastewater Program

Governments large and small should consider a condition-based maintenance program, leveraging acoustic-based technology. With taxpayer money on the line, it’s critical to look for ways to optimize and automate operations. The amount of time spent cleaning pipes that don’t need to be cleaned can be reduced by assessing the pipes using acoustic-based technology and cleaning them based on their condition.

According to Churchill, the SL-RAT is “not here to replace cleaning or CCTV. Rather, it’s another tool in the toolkit to optimize resources.”

ACE Septic & Waste is proud to be a part of an industry that utilizes the latest and greatest technology to create unique solutions to age-old problems. The ACE team would like to thank Alex Churchill and the InfoSense team for a great presentation at WWETT. To learn more about InfoSense and the award-winning SL-RAT technology, follow them on LinkedIn.

To learn more about ACE Septic & Waste, you can contact us, or follow us on social media.