After Total Dynamic Head (TDH), measuring flow rate is the next most important calculation in either commercial or residential lift stations.

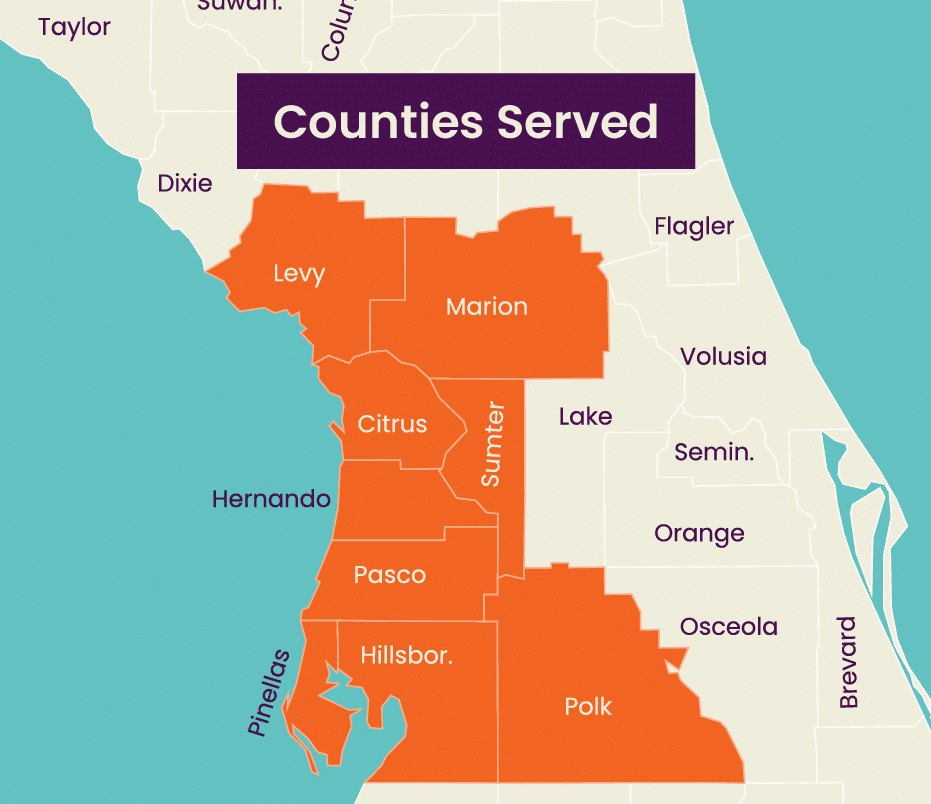

ACE Septic & Waste, we recognize that calculating the flow rate is pivotal in ensuring your lift station can efficiently handle sewage volumes without compromising performance. This article will cover how the flow rate formula is conducted and how anyone with a lift station in Tampa Bay or Central Florida can work with us to determine the equipment required based on the flow rate.

Data and Considerations

To calculate a flow rate, septic companies like ACE must first understand a customer’s unique situation. ACE Septic & Waste leaves no stone unturned when assessing lift station needs. We always consider factors like:

- Historical data

- Population and usage statistics

- Hydraulic modeling

- Flow monitoring

- Regulatory requirements

- Anticipated population growth.

Once we’ve gained these valuable insights, it’s time to put flow rate calculations into action.

Two Methods to Calculate Flow Rate

Calculating flow rate requires precision, and there are two methods ACE Septic & Waste relies on:

1. Using Pump Curve Data: This method is applicable when we have information about the pump’s performance characteristics. The formula used is:

Flow Rate (Q) = A ⋅ √H

- Q = Flow rate in cubic feet per second or gallons per minute.

- A = A constant that depends on the pump’s characteristics, such as design and efficiency.

- H = The total dynamic head (TDH) in feet.

2. Velocity-Area Method: This approach is employed in gravity-based sewer systems. It necessitates the calculation of velocity and cross-sectional area of flow in a pipe or channel:

Flow Rate (Q) = A x V

- Q = Flow rate in cubic feet per second or gallons per minute.

- A = Cross-sectional area of flow (in square feet or square inches).

- V = Velocity of flow in feet per second or inches per second.

Using the Velocity-Area Method, ACE would measure the flow’s velocity at a specific point in the sewer line and determine the pipe’s cross-sectional area at that location. By multiplying the area by the velocity, we calculate the flow rate with precision.

The Relationship Between Flow Rate and TDH

Flow rate and total dynamic head work together in lift station design. Doing so ensures optimal wastewater transport. While TDH defines the lift station’s hydraulic resistance, flow rate specifies the volume of sewage that needs to be transported. Together, they orchestrate an efficient and reliable lift station performance.

Choose ACE as your Tampa Bay and Central Florida Lift Station Service Provider

At ACE Septic & Waste, our commitment to excellence goes beyond numbers and formulas. We understand that calculating flow rates and TDH is more than a mathematical exercise; it’s about delivering wastewater management solutions that work seamlessly for you.

If you need lift station design, installation, or maintenance done right, trust ACE as your go-to expert. We partner with some of the community’s best and brightest engineers when conducting a lift station blueprint, meaning our collective team is thinking through the first stage to the last stage of your project. Contact us today for a consultation. For the latest updates in wastewater management, follow us on LinkedIn. At ACE, we turn complex calculations into straightforward solutions.

Your lift station’s efficiency starts here.